Wandwire Sp. z o.o.(Poland) specialises in production of high-quality spring steel cutting wires for the autoclaved aerated concrete (AAC) manufacturing facilities. We pride ourselves on being specialists in the production of made-to-size cutting wires tailored specifically for AAC plants. Our products can be used in any factory production technology from Hebel, Siporex, Ytong to Aircrete Europe, Hess AAC Systems, Masa Henke, Wehrhahn or WKB Systems. Whether you're producing AAC blocks, AAC panels or AAC lintels, we have the perfect cutting solutions to elevate your production process.

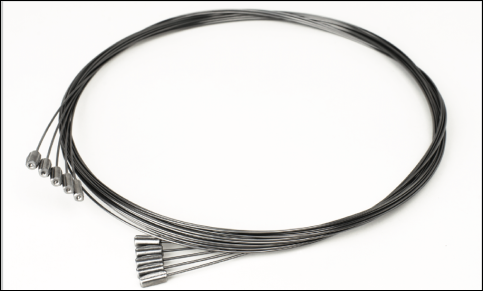

| Position | Wire length between nipples [mm] | Wire Ø [mm] | Nipple size [mm] | Coil surface treatment |

|---|---|---|---|---|

| Cutting wire (ready to use) |

Any | 0.6 - 1.5 * | 8, 10, 20, 25 | Phosphated or Polished ** |

*Multiple beads on each wire are possible

**According to EN 10270-1 (old DIN 17223 Class II)

| Position | Coil diameter [mm] | Coil surface treatment | Minimum order quantity |

|---|---|---|---|

| Spring steel coils * | 0.5 - 1.5mm | Phosphated or Polished | 20 kg |

* High-tensile strength coil (2350 - 2650 N/mm2) as per EN 10270-1 (old DIN 17223 Class II)

| Position | Outside Ø [mm] | Length [mm] | Internal Ø [mm] |

|---|---|---|---|

| Nipples / Ferrules | 5 | 8, 10, 20 | 0.8, 1.0, 1.1, 1.3 |